Well-designed Ultrafiltration Design Calculations - MCR Membrane Module Reinforced PVDF BM-SLMCR-30 Replacing Project – Bangmo

Well-designed Ultrafiltration Design Calculations - MCR Membrane Module Reinforced PVDF BM-SLMCR-30 Replacing Project – Bangmo Detail:

Applications

● Purification of surface water.

● Reuse of heavy metal waste water.

● Pretreatment of RO.

Filtration Performance

Below filtration effects are proved according to the use of modified PVDF hollow fiber ultrafiltration membrane in different types of water:

| No. | Item | Water Output Index |

| 1 | TSS | ≤1mg/L |

| 2 | Turbidity | ≤ 1 |

Specifications

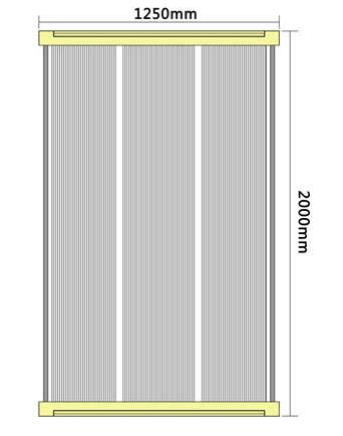

Size

Chart 1 MBR Size

Technical Parameters

| Filtering Direction | Outside-in |

| Membrane Material | Reinforced Modified PVDF |

| Precision | 0.03 micron |

| Membrane Area | 30m2 |

| Membrane ID/OD | 1.0mm/ 2.2mm |

| Size | 1250mm×2000mm×30mm |

| Joint Size | Φ24.5mm |

Component Material

| Component | Material |

| Hollow Fiber Membrane | Reinforced Modified PVDF |

| Sealing Compound | Epoxy Resins + Polyurethane (PU) |

| Housing | ABS |

Using Conditions

Proper pretreatments must be set when raw water contains a lot of impurities/coarse particles or large proportion of grease. Defoamer must be used to remove foams in membrane tank when necessary, please use alcoholic defoamer which is not easy to scale.

| Item | Limit | Remark |

| PH Range | 5-9 (2- 12 when washing) | Neutral PH is better for bacterial culture |

| Particle Diameter | <2mm | Prevent sharp particles to scratch membrane |

| Oil & Grease | ≤2mg/L | Prevent membrane fouling/sharp flux decrease |

| Hardness | ≤150mg/L | Prevent membrane scaling |

Application Parameters

| Designed Flux | 15~40L/m2.h |

| Backwashing Flux | Twice the designed flux |

| Operating Temperature | 5~45°C |

| Maximum Operating Pressure | -50KPa |

| Suggested Operating Pressure | ≤-35KPa |

| Maximum backwashing Pressure | 100KPa |

| Operating Mode | Continuous opeartion, intermittent backwashing air flushing |

| Blowing Mode | Continuous Aeration |

| Aeration Rate | 4m3/h.piece |

| Washing Period | Clean water backwashing every 1~2h; CEB every 1~2 days;Offline washing every 6~12 months

(Above information is for reference only, please adjust according to actual differential pressure change rule) |

Product detail pictures:

Related Product Guide:

To fulfill the customers' over-expected satisfaction , we have now our strong crew to provide our great general assistance which incorporates promoting, gross sales, planning, creation, high quality controlling, packing, warehousing and logistics for Well-designed Ultrafiltration Design Calculations - MCR Membrane Module Reinforced PVDF BM-SLMCR-30 Replacing Project – Bangmo , The product will supply to all over the world, such as: Sao Paulo , Ethiopia , Mauritius , Our tenet is integrity first, quality . We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

Write your message here and send it to us